Metal Fabrication

Sheet meta fabrication that strengthens your core competencies

TALK TO THE EXPERTS

Metal finishing services at ZhongXin

Metal finishing is a crucial process in our design-to-delivery metal manufacturing service. It allows us to support our customers with both fabricated assemblies and machined components ready for shipping or delivered directly to the end-user. Metal finishing treatments include in-house linishing, grinding and deburring, powder and wet painting, shot bead blasting, silk screening, engraving and more.

From a strong base of ISO approved suppliers, we can provide a range of specialist metal finishing services. These include heat treatment, zinc electroplating, anodising (both decorative and hard), phosphoric bond, hexavalent chromium-free and CARC.

All surface treatments are subject to rigorous quality standards and checks and undergo a full inspection before being dispatched or moving to assembly.All of our metal finishes are fully RoHS compliant, ensuring the processes used are free from any hazardous substances and compliant with the latest EU standards.

Whether your product would benefit from powder coating, bead blasting or anodising, we can advise you on the most suitable, sustainable, and cost-effective solution that meets your specifications.

Powder Coating

Powder coating is an essential part of ZhongXin’s complete metal manufacturing solution. Coating powders are electrostatically applied to prepared metals to provide a durable, attractive & even finish to metal surfaces.

Grinding & Deburring

Our grinding and deburring equipment includes belt sanders, bench grinders, angle grinders and linishers. These machines are able to offer any specified finish, capable of deburring pre-coated material such as Zintec and removing burrs with no detriment to the surface finish.

Plating

Electroplating is widely used in various industries for its numerous advantages. It provides a protective coating, enhances aesthetics, and improves corrosion resistance. This process finds applications in automotive, electronics, and jewelry manufacturing. Electroplating ensures durability, increases conductivity, and allows for customization. It is a cost-effective method for achieving desired surface finishes.

Anodization

Anodizing, a popular surface treatment, offers several advantages in various industries. It enhances the corrosion resistance of metals like aluminum, improves durability, and provides an attractive finish. Anodizing finds applications in automotive, aerospace, and construction sectors. This process allows for color customization, provides insulation, and increases wear resistance. Anodized surfaces are also easy to clean and maintain, making it a preferred choice for many applications.

PVD vacuum coating

PVD (Physical Vapor Deposition) coating is widely used in various industries due to its numerous advantages. It provides a thin, durable, and decorative coating on surfaces. PVD coating finds applications in automotive, electronics, and architectural sectors. It enhances wear resistance, improves hardness, and offers excellent adhesion. PVD coatings also provide corrosion resistance, reduce friction, and can be customized with different colors and finishes.

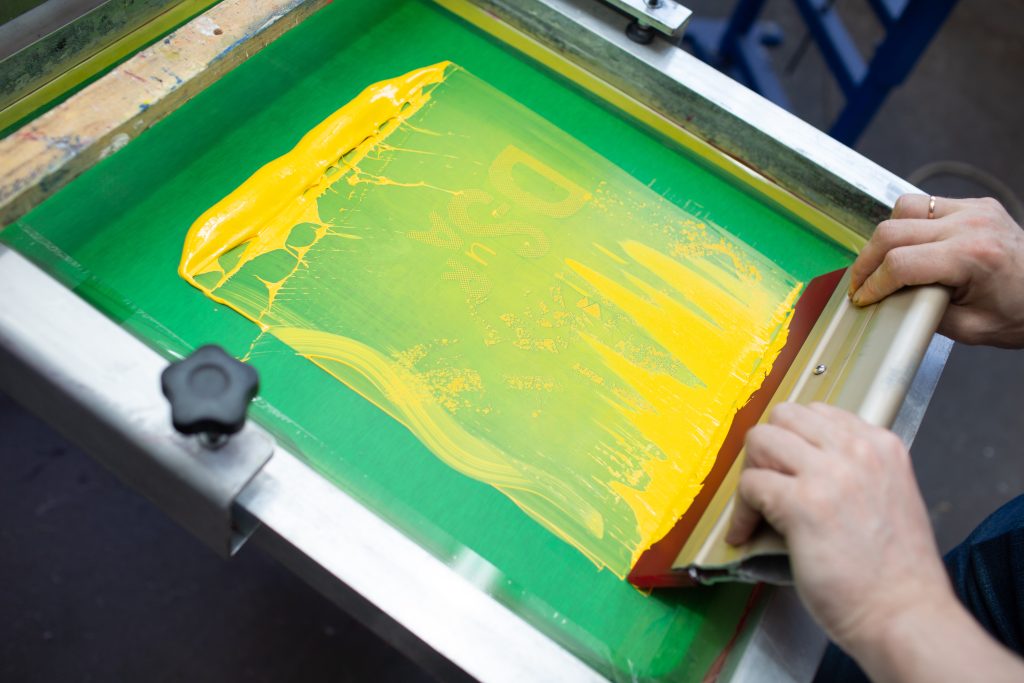

Finishing processes such as silk screen printing, tampo printing, pad printing and brand labelling allow ZhongXin to deliver various components and complete product assemblies to OEMs. ZhongXin runs rigorous tests to ensure adhesion and ink consistency on all metal printed components.

Stainless steel grades & finishes

Stainless steel fabrication offers a wide range of metal finishing techniques.

Sheet metal welding: MIG vs TIG

How to choose between MIG and TIG welding for the best results.

All about MIG & TIG welding services at ZhongXin

MIG and TIG welding use an electric arc to weld metal components together.

More On Metal Finishing Services At ZhongXin

Ask for a quote now

Zhong Xin specialises in the outsourcing of design, prototyping, sheet metal fabrication and precision engineering to provide OEMs with a higher return on outsourcing investment. We work to build strategic partnerships with our customers to strengthen core competencies and allow them to achieve complete supply chain continuity.