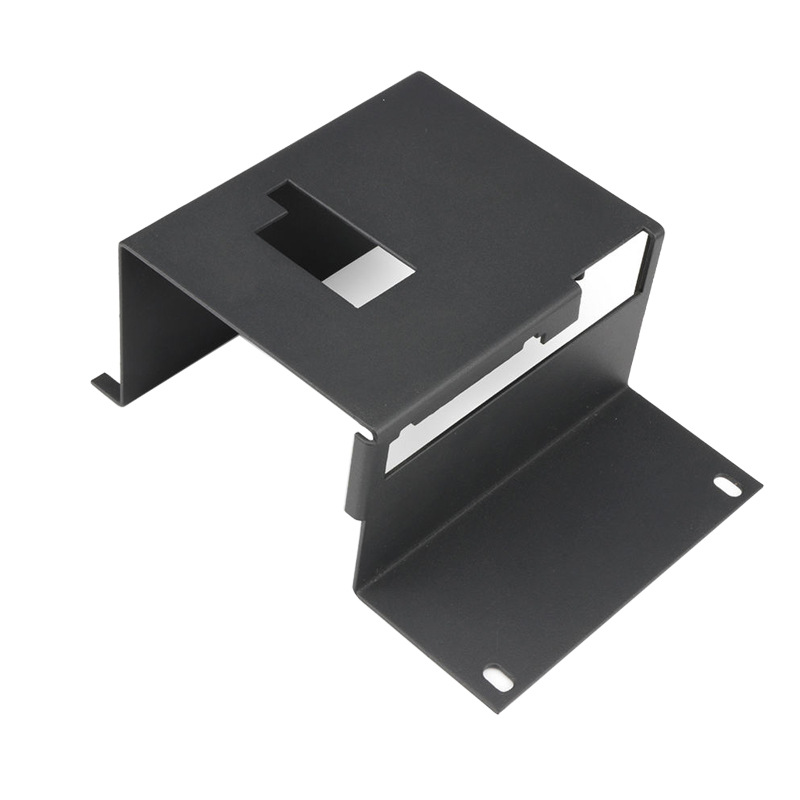

About the sheet metal folding process

Stainless steel has many uses in manufacturing thanks to its strength, resistance to corrosion and ease of use.

The metal is easily fabricated and has an attractive finish and is widely used in a range of industries including construction, automotive, medical and food processing.

There are more than 150 grades of the metal but around 15 are generally used in everyday applications.

Despite its relatively high strength, the material is malleable enough to be folded, machined, welded and finished in a wide variety of textures.

Modern fabrication technology allows the stainless steel to be cut, welded and processed as quickly and efficiently as other non-ferrous metals.

But, to ensure high-quality fabrication and to avoid any cross-contamination, it is important that workshops maintain separate processing facilities for ferrous and non-ferrous materials.

A quality steel fabricator must possess the technology, equipment and processes to produce quality products with ease.

If you have a question or enquiry about our services please get in touch.