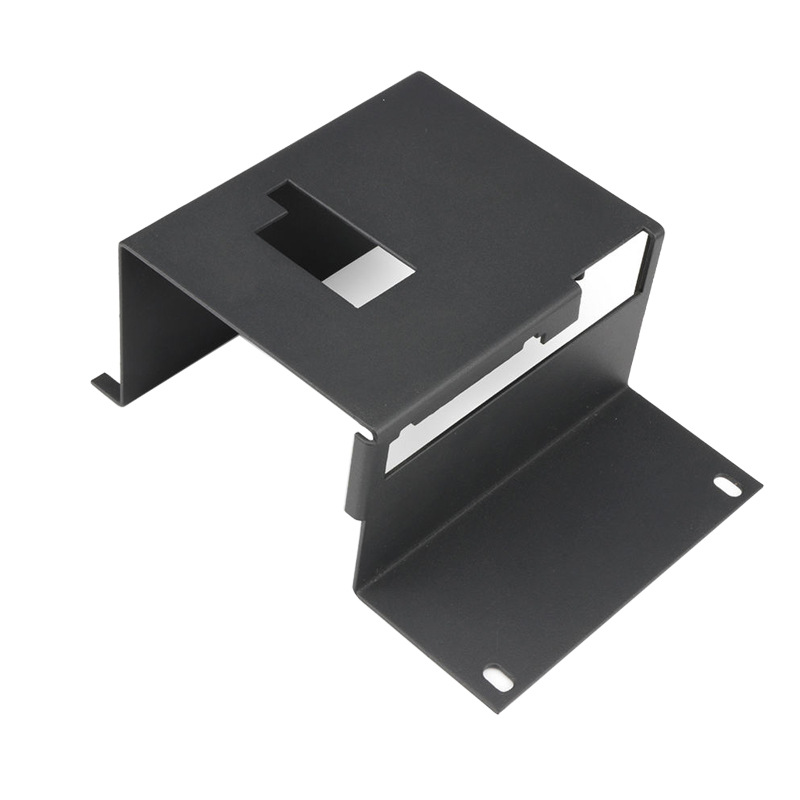

Sheet metal forming, folding & bending

Zhong Xin sheet metal is a leading supplier of sheet metal forming, folding and fabrication services in the UK and Europe. The company uses high-tech metal forming machines combined with the latest computer software to manufacture fully formed metal products.

Metal forming is the manufacturing process that involves bending metal sheets into the desired shape or geometry. The metal forming process involves a variety of factors to consider like strain hardening, temperature control, flow stress, and flexibility. Our team of experts work with a variety of these mechanical properties every day.

ZhongXin’s programme of continuous investment means it has manual metal folding and CNC folding solutions in a variety of formats. It allows us to select the most appropriate folding process to meet our customers’ needs. With press brakes, automated panel bending, and robot folding technology across the production line, ZhongXin delivers exceptional reliability and high-quality outputs.

Each aspect of the metal forming process plays its part in providing outstanding operational performance for any metal folding operation. This can range from small parts with a single bend to larger complex parts with many bows and multiple flange lengths.

If you would like to find out more about our sheet metal forming services, please contact our experts.

Metal Forming Capability:

Manual metal folding:

- Maximum component length: up to 3230mm

- Material thickness: up to 3mm

Automated metal folding:

- Maximum bending length: up to 2500mm

- Maximum material thickness: 2.5mm mild steel, 2mm stainless, 3mm aluminium

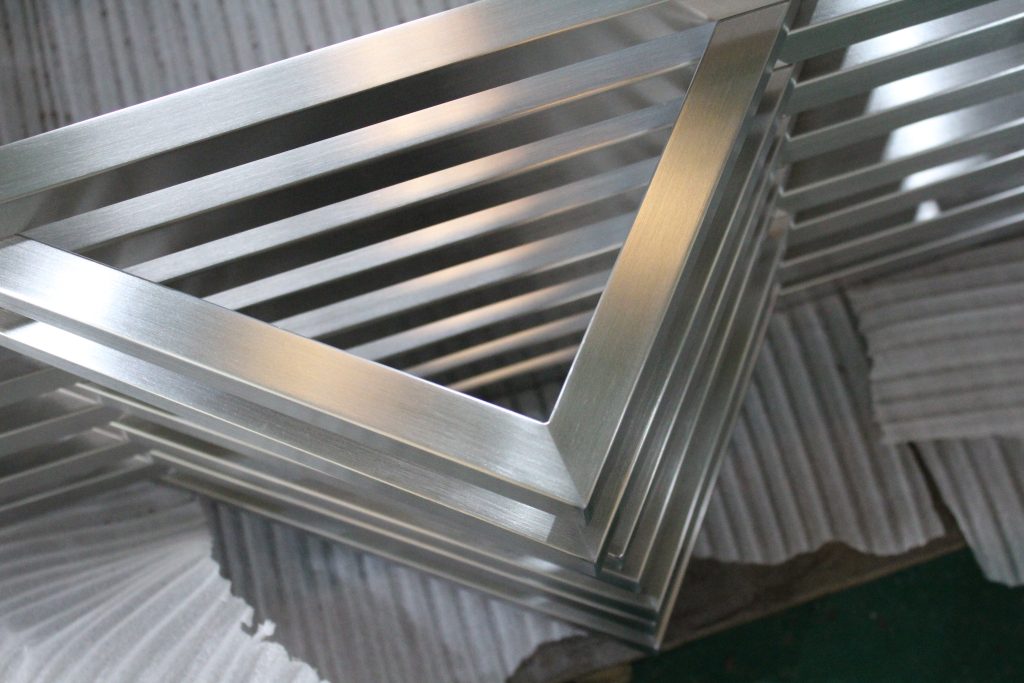

Material Types:

- Mild steel

- Galvanised steel

- Stainless steel

- Zintec

- Aluminium

About CNC metal laser cutting

Laser cutting is for precision work on metal plates in steel and aluminium.

About the sheet metal folding process

Bending, folding, punching and pressing sheet metal into a predetermined geometry.

All about stainless steel fabrication

Stainless steel benefits from strength, resistance to corrosion and ease of use.

More on metal forming & folding

Ask for a quote now

Zhong Xin specialises in the outsourcing of design, prototyping, sheet metal fabrication and precision engineering to provide OEMs with a higher return on outsourcing investment. We work to build strategic partnerships with our customers to strengthen core competencies and allow them to achieve complete supply chain continuity.