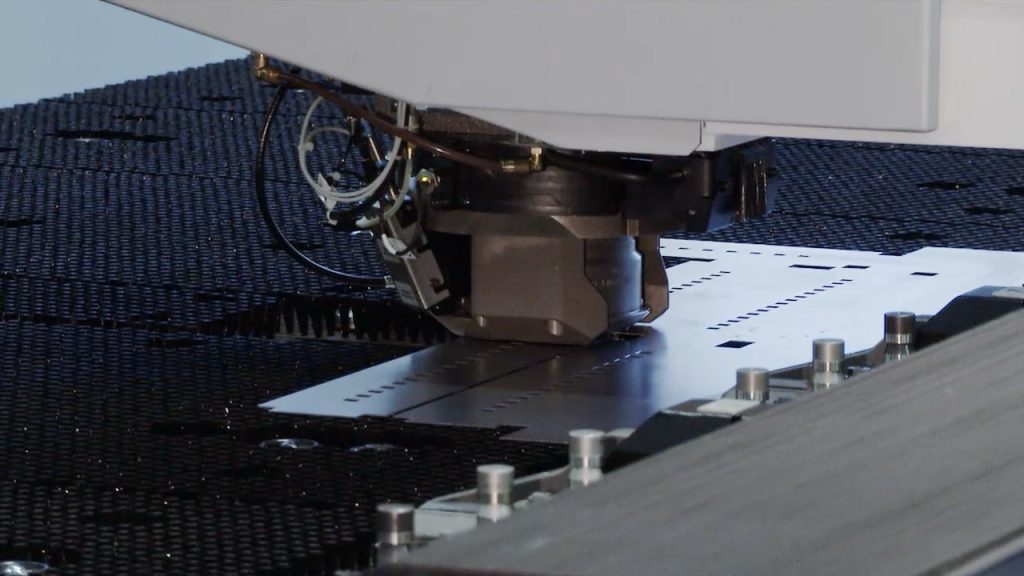

CNC metal laser cutting

Precision laser cutting operations at ZhongXin Precision Sheet Metal guarantees that sheet metal is cut with a high degree of consistency and precision.

The exceptional laser metal cutting department at ZhongXin boasts state-of-the-art technology, including Trumpf TruLaser machines. Our facilities offer high versatility and run lights out, 24 hours per day, seven days a week to deliver an array of sheet metal manufacturing products and assemblies for various industries.

Our Fiber Trumpf laser machines cut materials with a repetitive accuracy of 0.02mm. These include mild steel, stainless steel and aluminium in sheet sizes up to 3000 x 1500mm.

ZhongXin Group also operates Trumatic 6000 and 7000 combination laser/punch presses for added flexibility in metal cutting operations. These innovative combination machines give ZhongXin the ability to manufacture components that require both precision laser metal cutting and punching in a single process.

High-level laser cutting machine dynamics and the latest programming software give ZhongXin the capacity to produce any number of metal components most cost-effectively and efficiently.

We provide laser cutting for steel, aluminium, copper and other materials with competitive pricing, short lead times and exceptional results. Contact us to find out more about our cutting edge CNC laser cutting services.

Laser Cutting Capabilities:

Maximum Sheet Size:

- Up to 3000mm x 1500mm

Material Thickness:

- From 1mm to 25mm

Material Types:

- Mild Steel

- Stainless Steel

- Aluminium

- Zintec Galvanised Steel

- Coated Steels

- Copper

About CNC metal laser cutting

Laser cutting is for precision work on metal plates in steel and aluminium.

More on CNC metal punching

Sheet metal fabrication on sophisticated punch press machines.

Laser cutting: advantages & disadvantages

Pros and cons of laser cutting for sheet metal in steel and aluminium.

More On Metal Design & Prototyping

Ask for a quote now

Zhong Xin specialises in the outsourcing of design, prototyping, sheet metal fabrication and precision engineering to provide OEMs with a higher return on outsourcing investment. We work to build strategic partnerships with our customers to strengthen core competencies and allow them to achieve complete supply chain continuity.