All about stainless steel fabrication

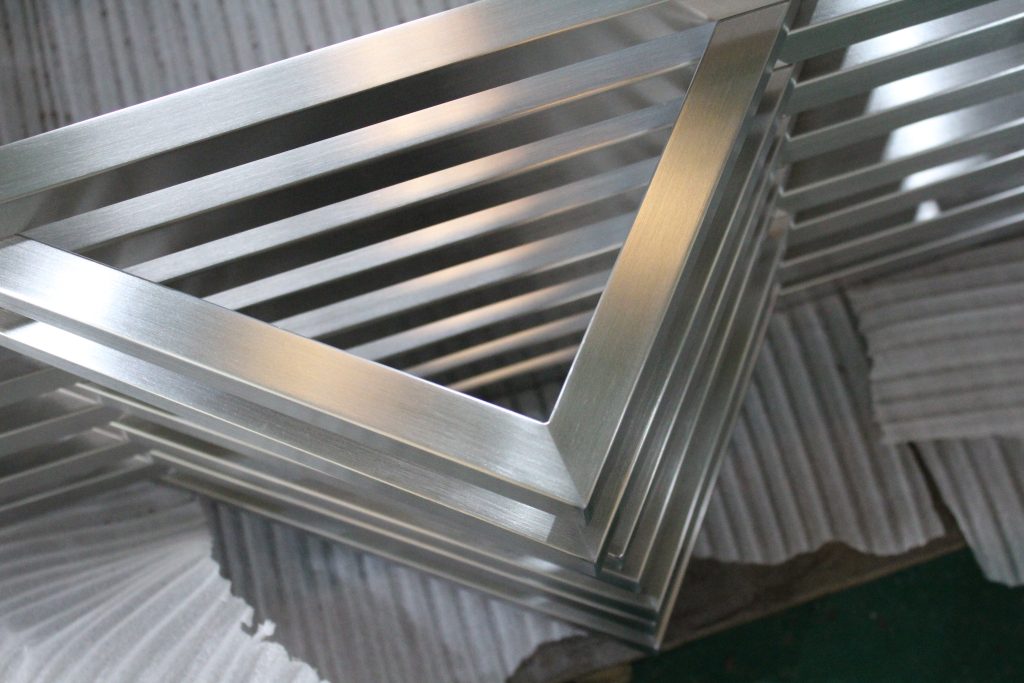

Sheet metal folding is the stage in the metal fabrication process and covers the bending, folding and pressing of sheet metal into a predetermined geometry.

Metal folding is used to create many products including pipes, enclosures, boxes and more, as sheet metal can be fashioned and reshaped in many ways such as rolling, indenting, bending and shearing.

The process is typically carried out on a press brake machine which uses strong tensile and shear forces to bend, fold and punch the sheet metal into the required shape.

However, advanced metal folding technology now includes automated panel bender machines and high-speed bending cells.

Press brake machines come in a range of sizes and types but most have a hydraulic ram with an upper punch that presses metal into a lower die. Press brakes can operate manually or automatically and many are computer-controlled.

Sheet metal fabricators often use advanced 3D CADCAM systems to help design and develop complex folded components and programs can be generated for batch production and stored electronically for later use.

Sheet metal folding is often just one process of many used in the manufacture of metal fabrications and is usually preceded by laser cutting or metal punching operations and followed by welding and assembly.

If you have an enquiry or any questions regarding our metal folding and metal bending capabilities, please do not hesitate to contact our customer service team.