More on CNC metal punching

What Is CNC Punching?

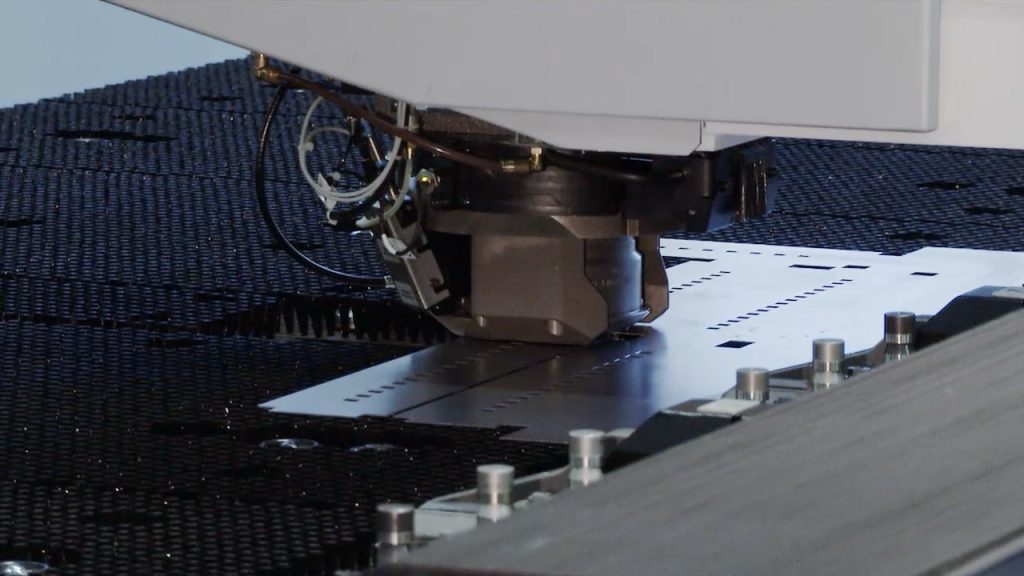

CNC punching is a modern sheet metal fabrication process that is carried out by computer-controlled punch press machines.

Punch presses use special rams to create holes or indent forms into sheet metal using dedicated computer software to position the ram.

The speed and efficiency demonstrated by CNC punching machines when manufacturing components with simple dimples, embossments or complex 3D perforated shapes is unrivalled.

Coupled with the ability to create cleanly edged shapes on a wide range and thickness of materials, CNC punch presses are central to the modern sheet metal fabrication industry.

Design details are fed into the punching machine directly from CAD/CAM design software which calculates the most efficient layout to maximise sheet utilisation and select the correct tooling to create the desired components.

Metal Punching Machine

The ability to position the metal sheet under the punching head with high precision accuracy affords great flexibility and the efficient processing of sheet metal.

Cluster tool systems can be used to reduce the set-up and tool changing time, improving the cost efficiency of the whole metal punching process.

For a specific sheet metal part, please contact our engineering team and we will investigate whether it can be CNC punched or whether it would be better suited to our CNC laser cutting machines.