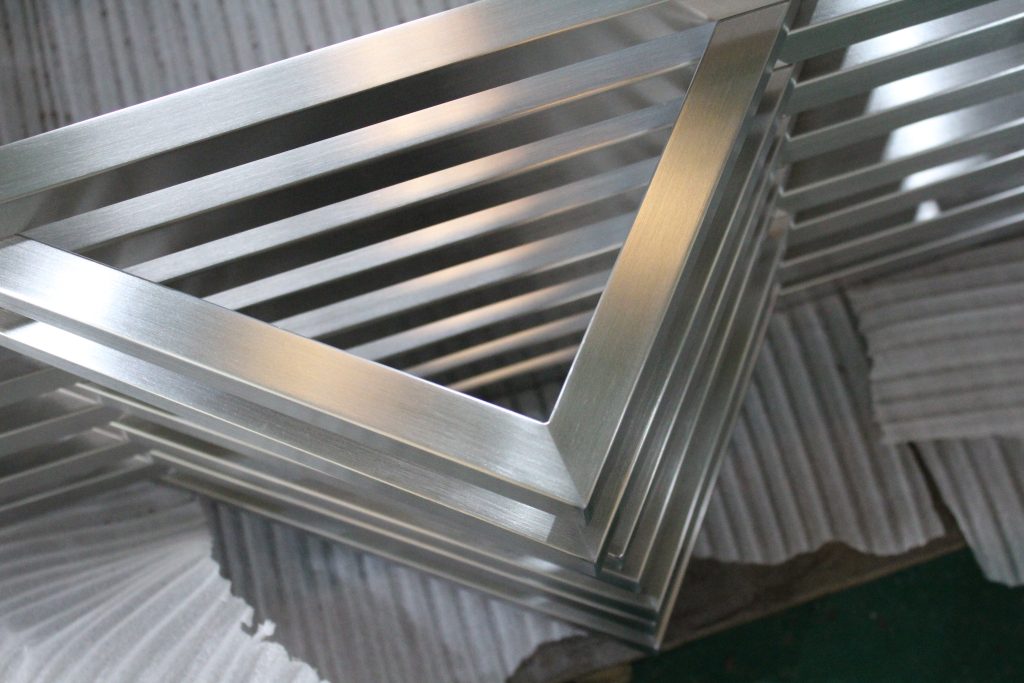

Stainless steel grades & finishes

Stainless steel is a popular material for sheet metal production. It is an iron-based alloy that contains at least 10% chromium and brings unique benefits such as high resistance to corrosion, heat and oxidisation.

Stainless steel sheet can vary in grades and finishes, all of which will affect the properties of the metal and so, to fabricate highly precise, durable components that use the material’s advantages, many factors need to be considered.

Grades Of Stainless Steel

The grades of metal most used in fabrication include 304, 316 & 430.

304-grade contains 18% chromium and 8% nickel and offers low-cost corrosion resistance to oxidisation, versatility and ease of fabrication. Grade 304 is austenitic and is often used to fabricate indoor products such as electrical enclosures, kitchen equipment and stainless hardware.

316-grade contains 2% molybdenum, which strengthens its resistance to chlorides, seawater, acidic chemicals and heat. Grade 316 is therefore favoured for the manufacture of outdoor products and those placed in testing environments such as marine applications or oil equipment.

430-grade is a ferritic metal with good corrosion resistance (however less than 304) and particularly strong resistance to nitric acid. The grade is readily weldable, ferromagnetic, has high machinability and is less expensive than the austenitic grade 304. 430 is commonly used for domestic appliances, automotive trim products and metal fabrications for chemical applications.

With dedicated facilities, including on-site shot bead blasting and electro-mechanical assembly, ZhongXin Precision Sheet Metal is the UK’s leading sheet metal fabricator. Contact one of our experts today to discuss your fabrication project.